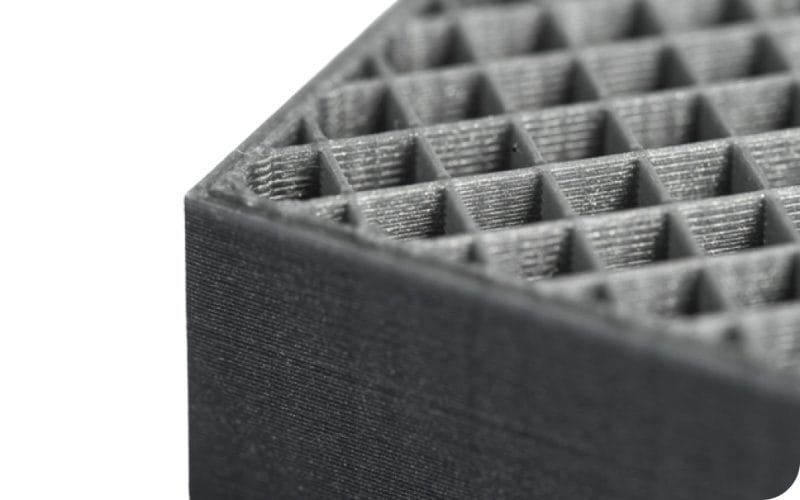

Fused Deposition Modeling

‘3D printing’ is commonly associated with maker culture, hobbyists and amateurs, desktop printers, accessible printing technologies like FDM and low-cost materials such as ABS and PLA (we’ll explain all those acronyms below). This is largely attributable to the democratization of 3D printing through affordable desktop machines that sprung from the RepRap movement, like the original MakerBot and Ultimaker, which also led to the explosion of 3D printing in 2009.