I have been using MakerWare (the default slicing program from MakerBot Industries) for quite some time now. Paired with proftweak it makes a powerful tool to edit and accommodate for specialty filaments including wood, nylon, filaflex and colorfabbs bronze and copper filaments.

The only limitations I came across were the lack of editable support material options and the excess amount of time it takes to slice something.

Enter SImplify3D.

From all the hype it could tackle all my problems including customisable support placement, ability to print multiple objects with different settings, easy to use and the rapid slicing time.

With so many other free, open source slicing solutions Simplify3D carried a hefty price tag of $149 USD and offered no sort of trial. Simplify3D had received so many great customer reviews and the internet was recommending it left, right and centre.

I fell for it and decided to run a few tests to compare the two slicing programs of which was quite surprising.

I used this model shown here

Both models were sliced with their default settings (for ease of use) at the following:

– 210 degrees

– 0.2mm layer height

– 90mm/s print speed

– Grey PLA

– 2 shells

– 20% infill

Simplify 3D – 10 seconds

MakerWare – 42 seconds

Simplify3D wins this round with a 400% faster slicing engine as compared to good old MakerWare.

Simplify 3D – 2 hours 19 minutes

MakerWare – 1 hour 29 minutes

MakerWare’s estimated build time was 50 minutes less than Simplify3D. With 50 minutes you’d be hoping to get considerably better quality.

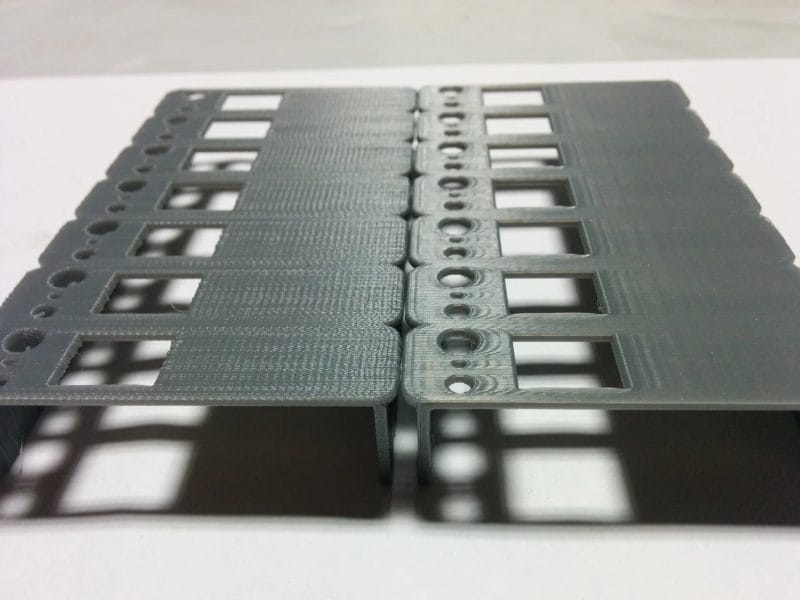

Each piece was printed individually on a Replicator 2. I will reveal which model belongs to whom at the end.

The left model is printed with clearly visible lines either due to over-extrusion or vibration along the print bed of which this is not visible in the right model. I must add that both models handled bridging and the circular holes very well, however the model on the right seems much more cleaner.

The model on the left belongs to the gcode generated by Simplify3D while the model on the right belongs to MakerWare.

LEFT – Simplify3D

RIGHT – MakerWare

Not only did Simplify3D take longer to complete but also produced a piece of poorer quality.

Im sure if the settings were tweaked – outer perimeter speed, filament diameter and extrusion flow you could achieve a presentable piece but at its default Replicator 2 settings, unfortunately at this point, it doesn’t seem to live up to the hype.

781 high st. reservoir vic 3073, australia