Western Australia has always been known for engineering strength, mining innovation, and industrial scale operations. As industries evolve, the demand for advanced manufacturing solutions continues to grow. This is where...

Read More >3D files are created by many methods, each with their benefits and drawbacks. We utilise the following techniques to create high-quality 3D printable files that meet your design requirements.

3D Printing Service

Explore reliable and customizable 3D printing solutions tailored to your unique project needs.

3D Printing Technologies

Learn about cutting-edge techniques that power efficient and precise 3D printing.

Materials

Discover a variety of durable and high-quality 3D printing materials for every application.

Applications & Benefits

Understand the versatile uses and advantages of modern 3D printing technology.

About 3D Printing

Get insights into the world of 3D printing and how it’s transforming industries.

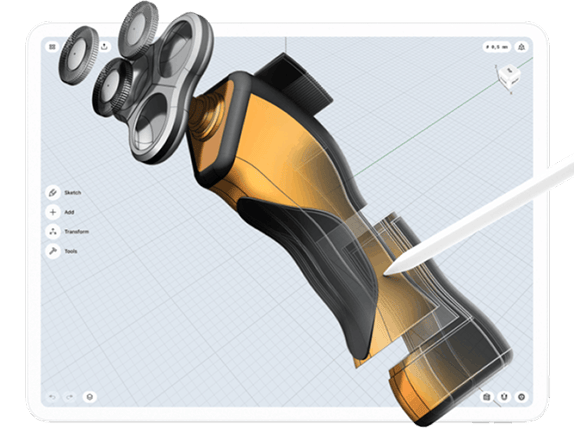

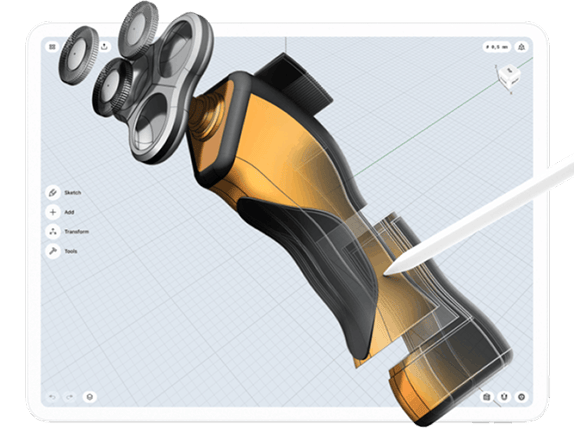

Our 3D Printing Design Engineering Solutions combine design knowledge, experience and expertise from multiple disciplines and the latest softwares to provide the source for your product design and development needs.

KAD3D uses the top of the line 3D modelling softwares best fit for your applications. With our highly experienced 3D engineers your idea can be tested and made come true.

Click here to try our material selection tool to help you find the best material for your project.

Reverse Engineering

Laser Kerf.

0.1 – 19.1 mm

Material Thickness.

790 x 384mm

Large parts.

Join 13,000 happy customers

checkout our application and benefits

Western Australia has always been known for engineering strength, mining innovation, and industrial scale operations. As industries evolve, the demand for advanced manufacturing solutions continues to grow. This is where...

Read More >Speed has become one of the most valuable assets in modern manufacturing. Whether you are launching a startup, testing a prototype, replacing a broken machine part, or producing custom components,...

Read More >South Australia has built a strong reputation in defense, automotive innovation, research, and advanced manufacturing. Within this ecosystem, Adelaide 3D Printing has become a powerful solution for rapid prototyping and...

Read More >As additive manufacturing continues to grow, more businesses are searching for the best 3d printing service in Australia that offers quality, reliability, and technical excellence. While many providers offer basic...

Read More >Brisbane is quickly establishing itself as a hub for product design, engineering, medical innovation, and research. In today’s competitive environment, the ability to iterate designs quickly and produce high-quality prototypes...

Read More >Melbourne has emerged as a hub for innovation, engineering, architecture, and research. Companies and startups in the region require fast, precise, and flexible manufacturing solutions to stay competitive. Traditional prototyping...

Read More >Sydney is home to a rapidly expanding ecosystem of startups, engineering firms, product designers, architects, medical professionals, and research institutions. As product development cycles become shorter and competition intensifies, access...

Read More >Traditional manufacturing methods often impose design constraints. Internal cavities, interlocking mechanisms, and complex channels can be difficult or expensive to produce using CNC machining or molding. An SLS 3D print...

Read More >In industries such as medical planning, architecture, and scientific research, color is not decorative. It carries meaning. Differentiating between anatomical structures, utility networks, or structural stress zones often requires more...

Read More >

Leverage over 30 years of expertise in 3D printing and additive manufacturing for industries like military, space, and commercial markets. Get an instant quote to kickstart your project now!