In the world of additive manufacturing, when you need strong functional parts, complex internal geometries, and no need for support structures, SLS 3D printing is one of the go-to technologies.

Rather than extruding filament or curing liquid resin, SLS uses a laser to fuse fine powder creating robust parts with mechanical properties rivaling injection molding.

Whether you’re a product designer, engineer, or maker, understanding SLS in 3D printing from materials to costs to its process, lets you pick smarter, design better, and avoid surprises.

Here’s a deep dive into SLS 3D printing step by step, with tips, tradeoffs, and real-world insights.

What Is SLS 3D Printing?

SLS stands for Selective Laser Sintering, a prominent member of the powder-bed fusion family of 3D printing.

In SLS 3D printing technology, a high-powered laser selectively sinters (i.e. fuses together) particles of powdered material layer by layer, building a solid object inside a bed of unfused powder.

Because the unsintered powder supports the structure during printing, no dedicated support structures are needed.

Brief History & Context

SLS was developed in the 1980s, soon after SLA 3D printing technology, and has since evolved for industrial use.

Over time, it’s become a backbone technology for functional prototyping and low-volume production, especially for parts that demand strength, durability, and geometric complexity.

The Core Principle

At its heart, SLS 3D printing relies on laser sintering of powder materials:

- A layer of powder is spread across the build area.

- A laser moves along the layer, heating the powder locally to just below or at its melting point, causing particles to fuse (sinter) together.

- The build platform lowers (or a recoater raises) to allow a fresh layer of powder.

- The process repeats, layer by layer, until the full part is complete.

Because only the targeted regions are fused, the surrounding powder remains loose and acts as natural support.

Other supporting mechanisms include:

- Preheating the powder bed near melt temperature to reduce thermal gradients.

- Maintaining an inert or controlled atmosphere (e.g. nitrogen) to avoid oxidation.

This process allows for complicated internal geometries, overhangs, and fine detail that would be difficult (or impossible) with many other 3D printing methods.

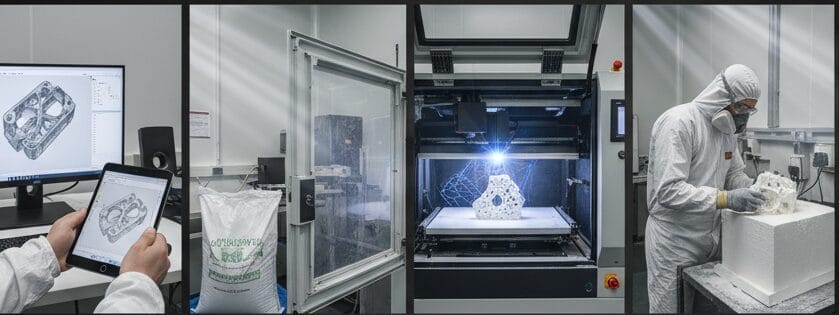

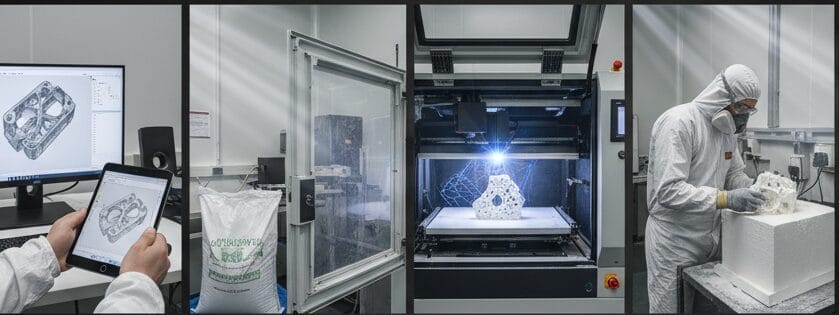

The Complete SLS 3D Printing Process

Below is how a typical SLS 3D print flows from model design to final part readiness.

Designing the 3D Model

- Use CAD software (SolidWorks, Fusion 360, etc.) to design a watertight model.

- Pay attention to wall thickness, clearances, vent/drain holes if hollow, and feature sizes.

- Export to .STL or .3MF formats, as with many other technologies.

Slicing & Pre-processing

- Feed the model into a slicing or preparation software (custom for SLS printers).

- The layers are defined; the laser path or scan strategy is planned.

- Options to set include layer thickness, scan type, power/laser parameters, and fill density.

Printer Setup

- Fill the powder hopper with the chosen material (typically nylon/PA, TPU blends, etc.).

- Preheat the powder bed & chamber to near the sintering temperature.

- Level the build surface and ensure the recoater or powder spreader is working.

- Define the build envelope and origin settings from software.

Layer-by-Layer Printing

- A thin layer of powder is spread.

- The laser scans along selected regions, fusing the powder there.

- The bed or recoater moves, new powder is spread, and the process repeats.

- Over time, your part “emerges” within the powder bed.

Depending on the part size, complexity, and printer capability, a build may take several hours or even days.

Cooling & Part Removal

- After sintering, the entire powder bed must cool slowly to reduce stresses and warping.

- Once cooled, the completed part is carefully removed from the powder cake.

Post-Processing

- Depowdering / cleaning: Remove loose powder using air blow, brushes, or media.

- Bead blasting or tumbling to smooth rough surfaces.

- Dyeing / coloring: Many nylon parts are dyed post-print.

- Sealing / vapor smoothing: Optional smoothing treatments to reduce surface roughness.

- Machining / finishing: For tight tolerances or final geometry tweaks.

- Quality inspection: Dimensional checks, mechanical testing, etc.

These post steps are vital, especially for functional parts and aesthetics.

SLS 3D Printing Materials & Their Uses

One of the strengths of SLS (Selective Laser Sintering) is the diversity of powder materials available.

Material Type | Properties / Advantages | Common Use Cases |

| Nylon / Polyamide (PA12, PA11) | Balanced strength, good thermal & chemical resistance | Functional prototypes, end-use parts |

| Glass-filled Nylon | Higher stiffness, better heat performance | Structural parts, load-bearing components |

| Carbon-fiber Nylon | Improved stiffness, lightweight | Aerospace, automotive, structural parts |

| TPU (flexible) | Elastic, impact-absorbing | Flexible joints, grips, elastomeric parts |

| Other additives / blends | Customized thermal, electrical, or mechanical properties | Specialty parts, custom blends |

Polymers dominate in polymer SLS. Metals may be processed via Selective Laser Melting (SLM) or other variants, but pure SLS metal 3D printing is less common.

Because powders come in fine particle sizes and special flow / sintering formulations, the powder properties (particle size, shape, distribution) strongly influence print quality and consistency.

Key Parameters That Affect SLS Print Quality

To get good results with SLS 3D print, optimizing these parameters is crucial:

- Layer Thickness: Typically ~50–120 microns. Thinner layers = more detail but slower print.

- Laser Power / Scan Speed: Must be tuned so powder fuses just right overpower causes irregularities, underpower causes weak bonds.

- Powder Bed Temperature: Keep very near melting point to reduce thermal stresses and warping.

- Scan Strategy / Hatch Spacing: How the laser traces influences internal stress and surface quality.

- Refresh Ratio / Powder Reuse: Unfused powder is reused but gets “aged” managing refresh % is vital.

- Packing / Nesting Density: How tightly parts are packed in the bed affects efficiency.

- Cooling Rate / Thermal Management: Poor cooling causes warping, residual stress.

- Post-processing Methods: Finishing, blasting, smoothing steps affect final surface, tolerance, and aesthetics.

Fine-tuning these leads to professional-grade SLS 3D printed parts.

Advantages of SLS 3D Printing

No Support Structures Needed

In SLS 3D printing, the surrounding powder naturally supports overhangs and internal geometries. This eliminates the need for separate support structures, saving material and post-processing time.

Strong and Functional Parts

SLS 3D printed parts have excellent mechanical properties often close to injection-molded strength. This makes the process ideal for functional prototypes and end-use parts.

High Design Freedom

The technology allows complex shapes, internal channels, and lattice structures that are difficult to produce with traditional methods.

Wide Material Compatibility

A variety of SLS 3D printing materials such as nylon, TPU, and composite powders can be used depending on the application.

Scalable Batch Production

Multiple parts can be printed together in one build, making SLS 3D printing services cost-effective for small-batch manufacturing.

Reduced Material Waste

Unused powder can often be recycled and reused, minimizing material wastage and overall SLS 3D printing cost.

Limitations & Challenges of SLS 3D Printing

Rough Surface Finish

Parts from SLS 3D printers have a grainy texture and may require sanding or polishing to achieve a smooth finish.

Powder Handling & Safety

Fine powders require proper ventilation and handling precautions, especially in industrial environments.

High Equipment and Material Cost

SLS 3D printing machines are expensive, and the specialty powders used also add to the overall cost.

Warping and Dimensional Accuracy

Thermal stress can cause part distortion or shrinkage if not carefully managed during the SLS 3D printing process.

Long Cooling and Cleaning Time

Post-processing steps like cooling, depowdering, and cleaning can make the total production cycle longer.

Applications of SLS 3D Printing

Prototyping and Product Development

Ideal for creating durable prototypes that can be tested for form, fit, and function.

Low-Volume Production

Used for small-batch manufacturing where traditional tooling is not cost-effective.

Aerospace & Automotive

Perfect for lightweight ducts, brackets, and functional parts requiring strength and precision.

Medical & Healthcare

Commonly used for prosthetics, anatomical models, and surgical planning tools with biocompatible materials.

Consumer Products

From electronic enclosures to wearable accessories, SLS 3D printed parts offer strength and design flexibility.

Flexible & Elastomeric Parts

With materials like SLS TPU 3D printing, flexible and shock-absorbing parts can be easily manufactured.

Custom and On-Demand Manufacturing

SLS 3D printing services allow rapid production of custom parts without tooling delays ideal for small businesses and startups.

FAQs

What is SLS in 3D Printing?

SLS (Selective Laser Sintering) is an additive manufacturing process that uses a high-powered laser to fuse powdered materials, usually nylon or composites into solid parts. It’s widely used for functional prototypes and end-use components because of its durability, precision, and design flexibility.

How Does SLS 3D Printing Work?

In SLS 3D printing, a thin layer of powder is spread across the build platform. A laser selectively fuses the powder based on the 3D model’s cross-section. The process repeats layer by layer until the part is complete, followed by cooling and depowdering. The unused powder acts as support and can often be reused.

What Does SLS Stand For in 3D Printing?

SLS stands for Selective Laser Sintering. It’s one of the most advanced 3D printing technology, known for producing strong, detailed, and functional parts without requiring support structures.

What is the largest size can print with SLS?

The maximum build volume depends on the specific SLS machine. Some industrial SLS printers can handle parts up to several hundred millimeters per side, while smaller machines are more limited. If your design exceeds the build envelope, it’s often split into sections and assembled later.