3D printing has evolved into a powerful manufacturing tool, and two technologies, FDM (Fused Deposition Modeling) and SLA (Stereolithography) dominate the desktop and industrial markets. Whether you’re choosing a new machine or simply trying to understand the differences between FDM vs SLA, this guide explains everything you need to know: print quality, speed, strength, materials, cost, applications, and more.

This detailed comparison will help you decide which one best fits your needs

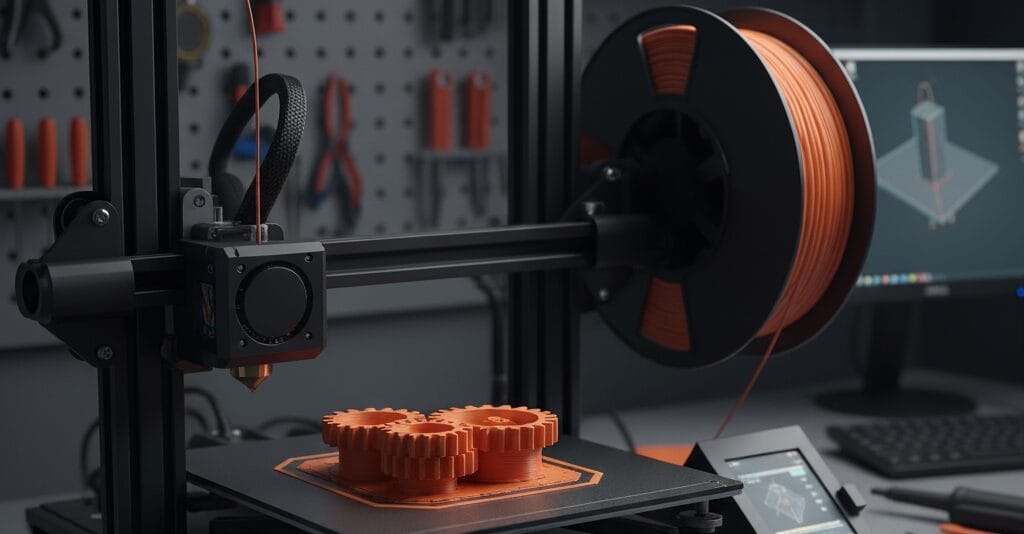

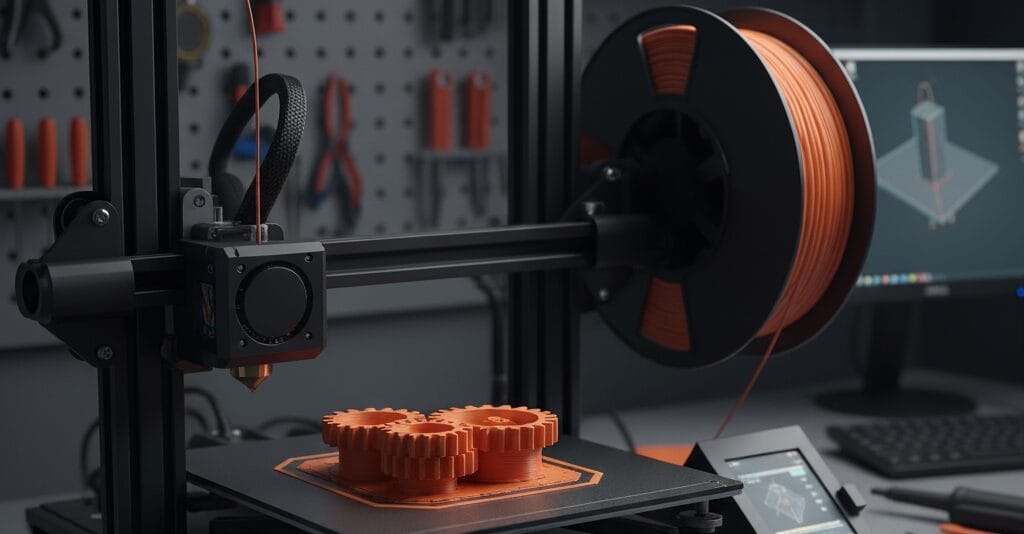

What is FDM 3D Printing?

FDM 3D printing also known as FFF (Fused Filament Fabrication), is the most common and beginner-friendly 3D printing technology. Instead of resin, FDM printers use solid thermoplastic filament like PLA, PETG, ABS, or TPU.

The printer heats the filament until it melts and then lays it down one layer at a time, building the object from the bottom up. Think of it like a very precise hot glue gun that draws your part layer by layer.

How FDM Works

A spool of filament (PLA, ABS, PETG, TPU, etc.) is heated in a nozzle.

The printer deposits melted plastic layer-by-layer.

The part cools and solidifies into its final shape.

Advantages of FDM

Affordable printers and materials

Large build volumes

Strong mechanical properties (depends on layer bonding)

Suitable for prototypes, large parts, jigs & fixtures

Limitations of FDM

Visible layer lines

Lower surface smoothness compared to SLA

Lower accuracy for small miniatures or intricate details

FDM is ideal for functional parts, engineering prototypes, and everyday practical prints.

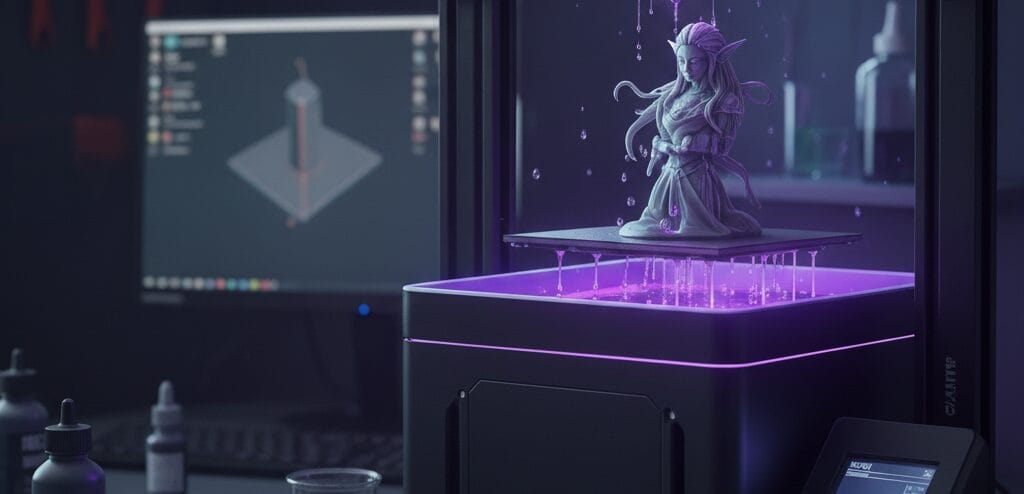

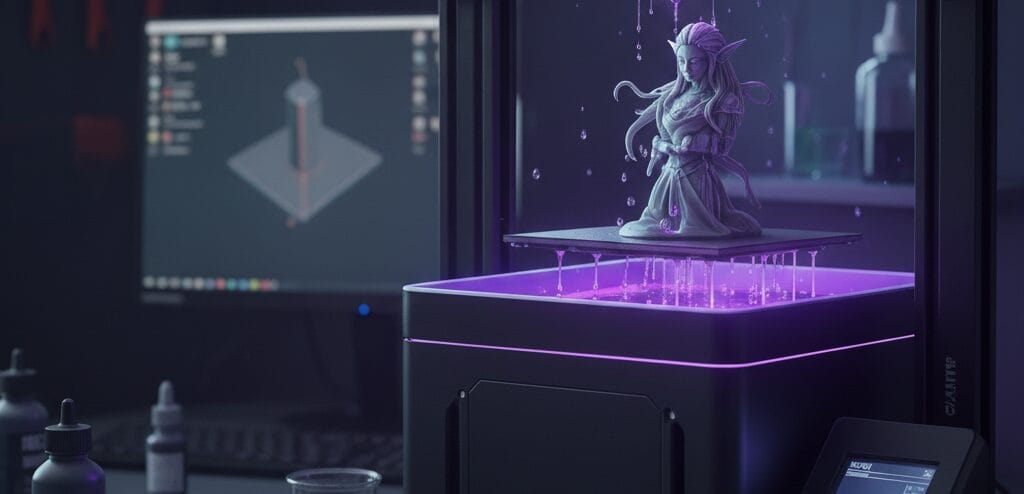

What is SLA 3D Printing?

SLA 3D printing (Stereolithography) is a resin-based 3D printing process that creates models using liquid photopolymer resin. Instead of melting plastic, an SLA printer uses a precise ultraviolet laser to draw each layer inside a tank of resin. Wherever the laser touches, the resin instantly hardens. This process repeats layer by layer until the entire part is formed.

How SLA Works

A vat of UV-sensitive resin is exposed to a laser.

The laser hardens the resin layer-by-layer.

The part is lifted from the tank and later washed and post-cured.

Advantages of SLA

Ultra-high detail and accuracy

Smooth surface finish

Excellent for miniatures, dental models, jewelry, molds

Limitations of SLA

Resin is more expensive

Post-processing required (washing + curing)

Toxic fumes; needs proper safety

Smaller build volume compared to most FDM printers

SLA is the best choice for detailed prototypes and highly aesthetic parts.

FDM vs SLA 3D Printing: Detailed Comparison

Looking to understand FDM vs SLA 3D printing? Here’s a detailed breakdown covering print quality, strength, speed, and materials, so you can choose the right 3D printer for miniatures, functional parts, and high-detail models.

Print Quality: FDM vs SLA

FDM 3D Printing Quality

Uses thermoplastic filament extruded layer by layer.

Visible layer lines are common.

Good for functional parts and mechanical components.

Struggles with miniatures or highly detailed prints.

Ideal if durability and material variety are important.

SLA 3D Printing Quality

Uses laser-cured liquid resin for each layer.

Near-injection-mold surface finish with ultra-smooth surfaces.

Perfect for miniatures, jewelry, dental casts, and high-detail prototypes.

Extremely fine details possible at 25–50 microns.

If print resolution is your priority in SLA printer vs FDM, SLA wins.

Print Strength: SLA vs FDM

FDM Strength

Stronger in impact resistance.

Better tensile strength.

Ideal for functional parts, mechanical components, and engineering prototypes.

Strong layer adhesion with materials like PETG, ABS, and Nylon.

SLA Strength

Resin prints are brittle compared to FDM plastics.

High detail but lower impact resistance.

Engineering resins exist but usually cannot match FDM durability.

Print Speed: FDM vs SLA Printing

FDM printers are generally faster for large objects.

SLA printers print at a consistent speed regardless of complexity but take longer per layer.

For small, detailed models, SLA can be efficient, but for large functional parts, FDM is faster.

Material Options: FDM vs SLA 3D Printing

FDM Materials

PLA, PETG, ABS, TPU, Nylon, Carbon fiber composites

Offers functional, durable, and heat-resistant options

Affordable and widely available

SLA Materials

Standard resin, Tough resin, Flexible resin, Dental & castable resins

Extremely high-detail printing

Requires post-processing (washing + UV curing)

FDM vs SLA Miniatures

SLA for Miniatures

High detail: Laser-cured resin captures intricate features perfectly.

Smooth surfaces: Prints come out almost ready-to-display without much finishing.

Crisp edges and fine features: Ideal for tabletop figures, jewelry models, or collectibles.

Smaller build sizes: Works best for tiny, detailed models.

FDM for Miniatures

Larger prints: Performs better with bigger models or props.

Durable parts: Stronger and less brittle than resin prints.

Visible layer lines: Smaller details may lose clarity unless post-processed.

Affordable and accessible: Easy to experiment without high material costs.

FDM vs SLA for Business Uses

Choose FDM if you need:

Durable mechanical parts

Functional prototypes

Large-scale printing

Lower cost per print

Choose SLA if you need:

High-detail visual prototypes

Dental/medical models

Jewelry molds

Miniatures and aesthetic parts

FDM vs SLA: Full Technology Overview

FDM

How it works: Melts thermoplastic filament and deposits it layer by layer.

Strengths: Strong, durable, and ideal for functional parts.

Cost & Size: Affordable printers and materials; good for large prints.

Limitations: Layer lines are visible; less detailed for fine models.

SLA

How it works: Uses a laser to cure liquid resin layer by layer.

Strengths: Ultra-high detail and smooth surface finish; excellent for miniatures and prototypes.

Limitations: Resin is more expensive; smaller build volume; prints can be brittle.

FDM vs SLA: Side-by-Side Comparison

| Feature | FDM | SLA |

|---|---|---|

| Quality | Good | Excellent |

| Detail Level | Moderate | Very High |

| Strength | Stronger | More brittle |

| Speed | Fast for big prints | Fast for small prints |

| Material Cost | Low | High |

| Post-Processing | Minimal | High (wash + cure) |

| Surface Finish | Visible lines | Smooth |

| Best For | Functional parts | Detailed miniatures |

FAQs

Which is better, FDM vs SLA 3D printing?

When comparing FDM vs SLA, the better option depends on your needs. SLA gives much higher detail and smoother surfaces, making it ideal for miniatures and display models, while FDM offers stronger, more durable prints that are better for functional engineering parts. So in short, SLA wins for detail and FDM wins for strength and practicality.

Is SLA printing stronger than FDM?

In a direct sla vs fdm strength comparison, SLA is generally not stronger. Resin prints tend to be brittle, while FDM materials like PETG, ABS, and Nylon provide better toughness and impact resistance. For durability and real-world use, FDM prints outperform SLA.

Is FDM cheaper than SLA?

Yes, fdm printing is much cheaper overall. FDM printers cost less, the filament is affordable, and maintenance is simpler, while SLA resin, cleaning materials, and post-processing tools make SLA more expensive long term.

What’s the difference between SLA vs FDM 3D printing quality?

The quality difference between sla vs fdm printing is clear: SLA produces smoother surfaces and far cleaner details due to its laser-cured resin process, while FDM prints show visible layer lines but offer stronger mechanical performance. SLA wins visually, FDM wins structurally.

For 3D printing projects, quotes and more information visit KAD 3D