3D printing has rapidly evolved, and two technologies FDM (Fused Deposition Modeling) and MJF (Multi Jet Fusion) stand out for producing strong, functional parts. Whether you’re picking a machine for your business or simply trying to understand the difference between FDM vs MJF, this guide explains everything clearly: print quality, strength, speed, cost, materials, workflow, surface finish, and real-world applications.

This detailed comparison will help you decide which one fits your needs best.

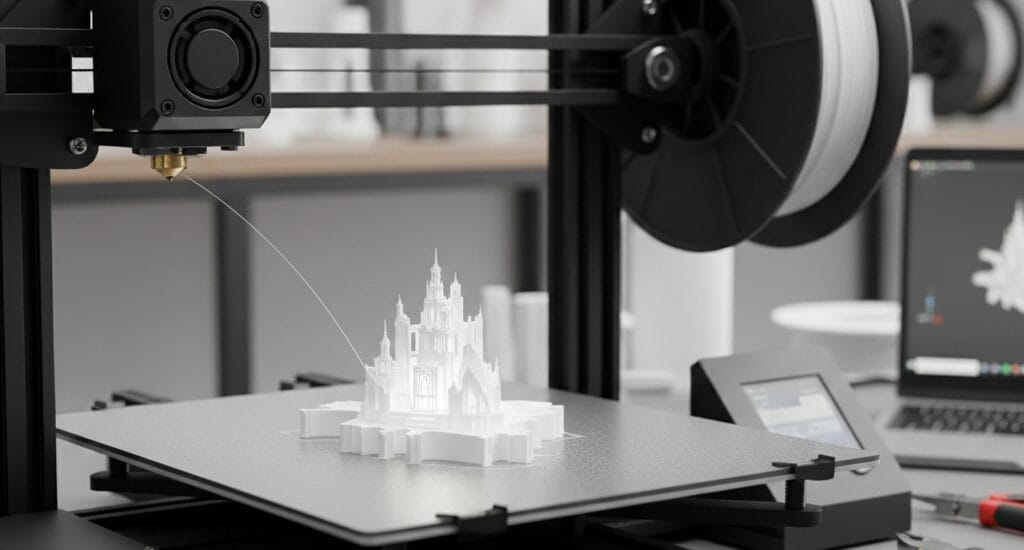

What is FDM 3D Printing?

FDM 3D printing, also known as FFF (Fused Filament Fabrication), is one of the most common and beginner-friendly 3D printing technology. It uses solid thermoplastic filament like PLA, PETG, ABS, or Nylon which is melted and extruded layer by layer.

Think of it as a controlled, ultra-precise hot glue gun that draws your part one layer at a time.

How FDM Works

A spool of filament (PLA, ABS, PETG, TPU, Nylon, etc.) is heated in a nozzle.

The printer extrudes melted plastic layer-by-layer.

The material cools, hardens, and builds the final shape.

Advantages of FDM

Very affordable materials

Large build volumes available

Good mechanical strength (varies with filament type)

Great for functional parts, jigs, fixtures, and prototypes

Easy workflow with minimal post-processing

Limitations of FDM

Visible layer lines

Lower detail compared to resin or MJF

Mechanical strength depends on layer bonding

Dimensional accuracy can vary

FDM is ideal for functional prototypes, engineering parts, large objects, and low-cost production.

What is MJF 3D Printing?

MJF 3D printing is an industrial 3D printing technology developed by HP. It uses powder-based Nylon material, which is fused by an infrared lamp after being coated with fusing agents. Unlike FDM, MJF does not extrude material instead, it fuses entire layers at once.

This allows it to produce highly accurate, strong, and repeatable parts ideal for manufacturing.

How MJF Works

A thin layer of Nylon powder (usually PA12 or PA11) is spread on the print bed.

A printhead jets fusing & detailing agents onto the powder.

An infrared lamp passes over, solidifying only the jetted regions.

The process repeats layer-by-layer until the part is complete.

Advantages of MJF

Excellent strength and isotropic mechanical properties

Highly accurate and consistent professional results

Smooth, uniform surface with minimal layer visibility

Ideal for batch production and functional components

No support structures needed

Limitations of MJF

Machines and materials are expensive

Requires powder-handling equipment

Limited material options (mostly Nylon-based)

Post-processing (depowdering) required

FDM vs MJF 3D Printing: Detailed Comparison

Looking to understand MJF vs FDM more clearly? Here’s a deep breakdown covering quality, strength, speed, materials, and applications so you can choose the right technology for your needs.

Print Quality: FDM vs MJF

FDM 3D Printing Quality

Prints thermoplastic filaments layer-by-layer

Visible layer lines are common

Good for general prototypes

Struggles with very fine details

Surface quality depends heavily on calibration

MJF 3D Printing Quality

Uses powder fused by an infrared lamp

Much smoother surface finish than FDM

Excellent detail and dimensional precision

Professional-grade accuracy suitable for end-use parts

Isotropic strength (almost equal in all directions)

Print Strength: MJF vs FDM

FDM Strength

Strength depends on filament type and layer adhesion

PLA = rigid but brittle

PETG = tough and impact-resistant

ABS/ASA = durable & heat-resistant

Nylon / CF-Nylon = strongest FDM filaments

Weakest point: layer separation under stress

MJF Strength

Uses Nylon powder (PA12, PA11)

Exceptional tensile & impact strength

Strong in all directions (isotropic)

Ideal for real-world mechanical parts

More durable than SLA and often stronger than standard FDM

Print Speed: FDM vs MJF

FDM Speed

Faster for single large objects

Slower for small detailed prints

Complex geometry increases print time

MJF Speed

Prints entire layers at once

Print time does NOT change with complexity

Extremely fast for batch production

Material Options: FDM vs MJF

FDM Materials

PLA, PETG, ABS, ASA

TPU (flexible)

Nylon

Carbon fiber composites

Wood-filled, metal-filled, glitter, etc.

Extremely diverse and budget-friendly options.

MJF Materials

Primarily Nylon PA12 (standard)

PA11 for higher flexibility

Glass-filled (PA12 GF)

TPU (in some MJF systems)

Industrial-grade powders

Material variety is limited but very high performance.

FDM vs MJF Surface Finish

FDM

Visible layer lines

Rougher surfaces

May require sanding, filing, or smoothing

MJF

Smooth, uniform surfaces

Almost no visible layers

Light post-processing needed (bead blasting, dyeing)

FDM vs MJF for Miniatures & Detailed Models

MJF for Miniatures

Clean surfaces

Excellent accuracy

Handles small details well

Very durable for handling/production

FDM for Miniatures

Visible lines reduce clarity

Not ideal for tiny details

Better for large props or display pieces

FDM vs MJF for Business & Industrial Uses

Choose FDM If You Need:

Low-cost prototypes

Large functional parts

Budget-friendly production

Simple engineering applications

Material experimentation

Choose MJF If You Need:

End-use manufacturing

High-strength functional parts

Batch production

Industrial-grade accuracy

Consistent mechanical performance

FDM vs MJF: Full Technology Overview

FDM

- How it works: Melts filament and extrudes it layer-by-layer.

- Strengths: Affordable, large prints, wide material choices.

- Cost & Size: Low material cost, cheap machines.

- Limitations: Visible layer lines, lower precision.

MJF

- How it works: Uses powder + fusing agent + infrared lamp.

- Strengths: Strong, accurate, fast, industrial-grade parts.

- Cost & Size: Expensive machines but great for production.

- Limitations: Limited materials, powder handling required.

FDM vs MJF: Side-by-Side Comparison

| Feature | FDM | MJF |

|---|---|---|

| Quality | Good | Excellent |

| Detail Level | Moderate | Very High |

| Strength | Depends on filament | Industrial-grade strong |

| Speed | Moderate | Very fast (batch printing) |

| Material Cost | Low | Medium–High |

| Machine Cost | Low | Very high |

| Surface Finish | Visible lines | Smooth, uniform |

| Best For | Prototypes & large parts | Functional end-use parts |

FAQs

Which is better FDM or MJF ?

The best choice depends on your needs. MJF produces stronger, smoother, and more accurate parts, making it ideal for end-use manufacturing and engineering applications. FDM is cheaper and great for prototypes, hobby printing, and large objects.

Is MJF stronger than FDM?

In most cases, MJF Nylon prints are stronger, more durable, and more isotropic than standard FDM filaments. Even strong FDM materials like Nylon or PETG cannot match the consistency of MJF.

Is MJF more expensive than FDM?

Yes, due to industrial machines, powder 3D printing materials, and post-processing. FDM is significantly more affordable for beginners and small workshops.

For 3D printing projects, quotes and more information visit KAD 3D